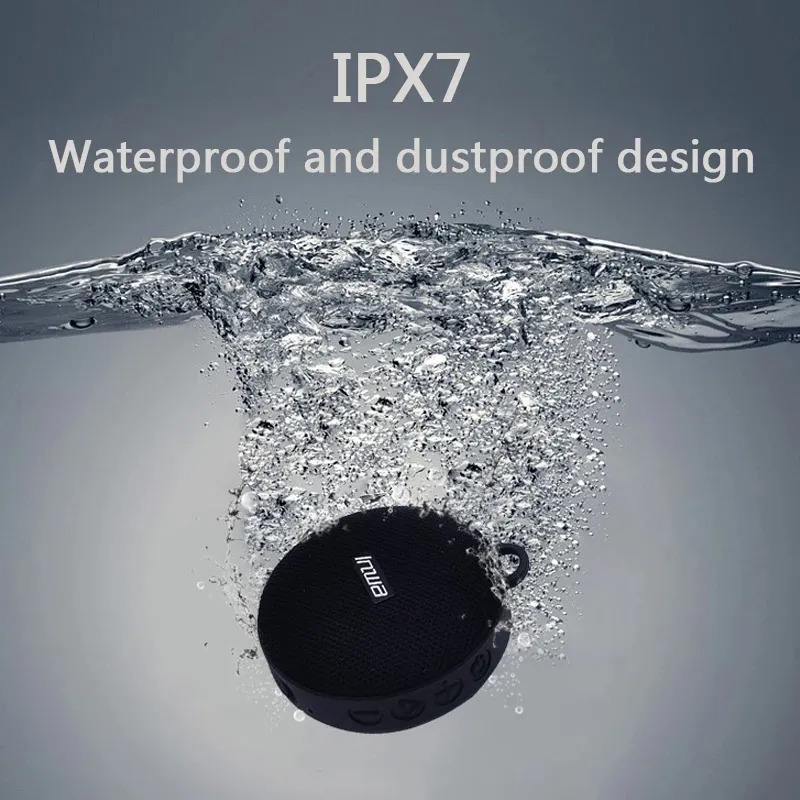

Most speakers are designed and manufactured for indoor working environments, and these speakers themselves do not have waterproof functions. When water comes into contact with these devices, it will cause serious damage to their performance and lifespan, making them unable to work properly. In addition, disassembly, movement, and portability are also inconvenient. So in daily life, speakers inevitably come into contact with water due to environmental factors, such as humid air, rainy days, outdoor travel, etc., which can have a certain impact on the operation of speakers. How to protect speakers well in the presence of water? So the choice of speaker is also an important factor. How to effectively waterproof the speaker, and how can the speaker work effectively and transmit sound during the waterproof process? Now let me introduce the waterproof speaker to you.

Waterproof speaker manufacturing process

- Shell of waterproof horn

The shell of the waterproof horn is made of several commonly used plastic materials such as LCP, PBS, PBT, PPO, PP, ABS, PET, PVC, etc., which are the latest high resin materials. They are melted at high temperatures and die cast from metal molds according to their designed shape and size. The selection of raw materials itself has certain flame retardant properties such as high temperature resistance, weather resistance, and corrosion resistance. The waterproof horn shell must also undergo waterproof spray painting treatment, and the coating wrapped around the shell increases the overall sealing of the waterproof horn.

- Waterproof horn waterproof membrane

The waterproof membrane of the waterproof horn adopts a new type of polymer waterproof material, which has a microporous membrane structure to provide excellent breathability. Moisture and steam are easy to dissipate, not easy to fall off, UV resistant, and high temperature resistant, and can effectively prevent dust and water. The waterproof membrane of the waterproof horn is generally thin and not thick, and has good penetration in sound to ensure sound transmission. The material of the waterproof horn waterproof membrane has certain stretchability, which can effectively protect internal components from the influence of liquids even under the pressure of the shell.

- Waterproof speaker unit

The exterior of the waterproof speaker unit is treated with special waterproof adhesive, which can effectively prevent water damage without affecting the structure of the waterproof speaker unit. The waterproof speaker unit is protected by the outer shell, which also avoids direct contact with water inside the waterproof speaker unit.

Waterproof speaker applicable scenarios

- Waterproof speakers are commonly used outdoors, such as square music fountains, park waterproof speakers, AI intelligent outdoor home communication systems, music concerts, etc. If the waterproof horn is exposed, it must undergo special waterproof treatment.

- The sealing of the waterproof speaker shell is crucial, and the internal unit structure needs to be waterproofed. The outdoor sports craze has driven the market for small Bluetooth speakers. After treatment, the waterproof speaker inside the Bluetooth speaker can be immersed in (1 meter deep water, 30 minutes without water ingress) and the waterproof level must reach IP67.